Rechner ATEX rated Inductive and Capacitive Sensors have built a reputation for reliability and durability over many decades. Sensory technology you can trust.

Kempston Controls Top Ten Blog Posts of 2019

After publishing 65 posts this year, we’ve decided to take this time to reflect and round-up our most popular articles this year. Here are our top ten blog posts from 2019:

E2E NEXT Proximity Sensors – When Proximity Matters

Proximity sensors are a staple when it comes to industrial process automation and control. The Omron E2E NEXT range is a step above the competition.

Supplier Round-Up from Kempston Controls

With so much to keep up with and all of the great content that is being published by our partners, we’ve been keeping up-to-date with all of their activities and have compiled a supplier round-up.

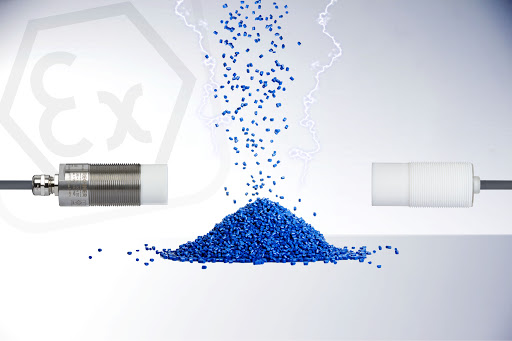

Top 5 Inductive Proximity Sensors

Inductive Proximity Sensors are the sensory power behind many industrial automation and control processes. We take a look at our top 5.

Inductive Proximity Sensors – the Smart Factory’s Friend

Industry applications are becoming more and more dependant on tracking, monitoring, measuring and communication and of course, that vital data is required instantly. That’s where Inductive Proximity Sensors come in…