The VISOR Object AI machine vision sensor from Sensopart, the intelligent way to vision monitor your manufacturing processes.

ATEX Sensors you can depend on from Rechner, Brought to you by Kempston Controls

Rechner is renowned for the creation of one of the widest ranges of fully certified ATEX sensors and probes available in the marketplace.

Inductive Sensors for Valve Position Detection – for Regular & Harsh Industrial Environments

Inductive proximity sensors for direct actuator mounting. Fast connection, easy replacement and compact, for any working environment.

SICK PBS plus Pressure Sensor – Added Versatility for Pressure Monitoring Installations

The PBS plus Pressure Sensor Range is the perfect sensor for demanding industrial applications, providing a robust electronic pressure switch, transmitter and display all in one.

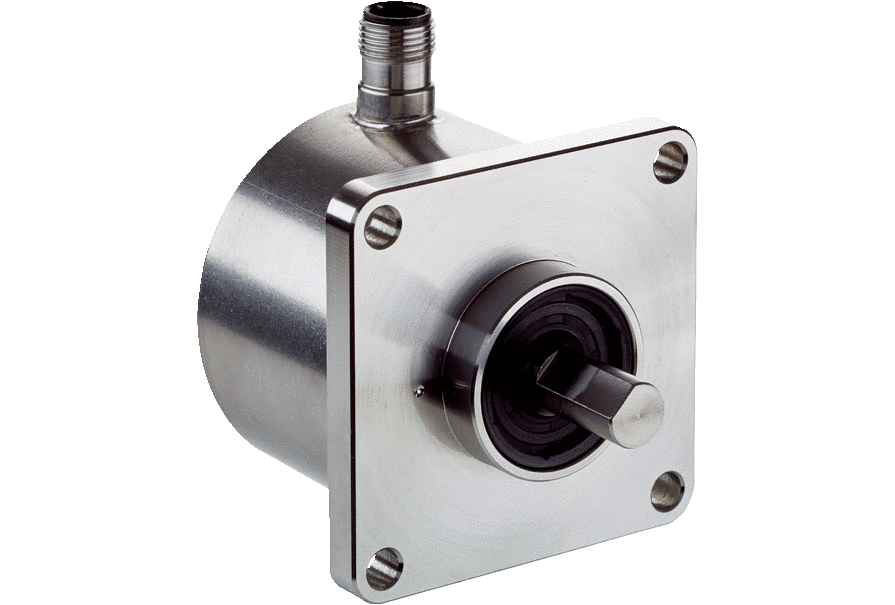

Incremental Encoders for Challenging Applications – the SICK DBS60 Inox Range

The rugged DBS60 Inox range of Incremental Encoders is the perfect position and speed monitoring encoder for harsh working environments.

R2000 2-D Lidar Sensors – Sensors with Depth Perception

The R2000 Series of LiDAR Sensors from Pepperl + Fuchs, an exceptional sensing solution for Position and Navigational systems.