Camozzi Automation and Kempston Controls have banded together to bring you the best in fluid management products.

Kempston Controls LLC and Tele Haase Steuergerate – a new partnership is formed.

Tele Haase Steuergerate and Kempston Controls LLC have formed a partnership designed to bring you the best in monitoring, automation and control products.

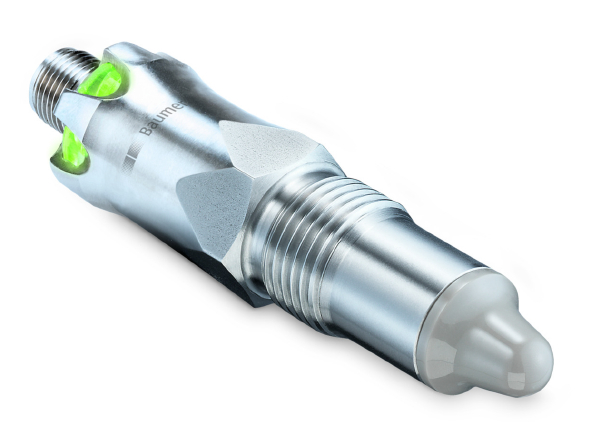

The King of Level Sensors – The KingCrown CleverLevel PL20 Series from Baumer

The Baumer KingCrown CleverLevel Level Sensors are a step above the competition. Ideal for Harsh Hygenic and Industrial Applications that utilise difficult media.

A Change is Brewing – the VLT AutomationDrive FC 302 – Making Beer Smarter

The VLT AutomationDrive FC 302 from Danfoss helped HEINEKEN increase uptime, reduce overheads and boost system performance.

Kempston Controls becomes Midlands distributor for Bürkert valves

Electrical component distributor, Kempston Controls, has become Bürkert’s official distributor for the Midlands region. Based in Northamptonshire, Kempston Controls now supplies end-users across the region with Bürkert’s range of process valves and flow control components. The main sectors of coverage include food & beverage as well as hygienic applications. The new agreement means that Kempston Controls […]

The PP20H Pressure Sensor from Baumer, the ideal Hygienic Pressure Sensor Solution

The Baumer PP20H Hygienic Pressure Sensor range is the ideal small form factor solution for dependable absolute and relative pressure and vacuum monitoring.