AC drives are an electronic brain for electric motor. They play a critical role in the operation of various types of industrial machinery.

A Pneumatic Connection – SMC Corporation (UK) Ltd. and Kempston Controls Team Up!

SMC Corporation (UK) Ltd. and Kempston Controls have combined to help bring you the best in pneumatic and automation and control products.

Camozzi Automation and Kempston Controls Team up!

Camozzi Automation and Kempston Controls have banded together to bring you the best in fluid management products.

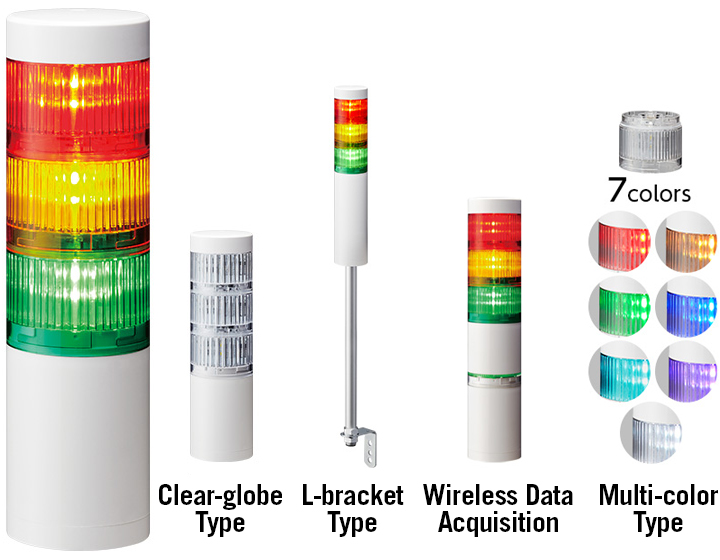

LR Series – LED Signal Towers – the Illuminating Choice, by PATLITE

The LR Series of Signal Towers are the perfect choice for harsh environment industrial signalling applications that you can depend on.

Lifting Africa with Dependable Crane Components from Kempston Controls Manufacturing

Cutler Hammer Compatible Crane Components from Kempston Controls Manufacturing. Reliability and durability, Made in Britain.

Cable Accessories when you need them – New from Kempston Controls

Cable Accessories – a new range of high-quality products to help you secure, protect and maintain your wiring installations.