Inductive Proximity Sensors are the sensory power behind many industrial automation and control processes. We take a look at our top 5.

The One With Our Top 5 Panel Meters

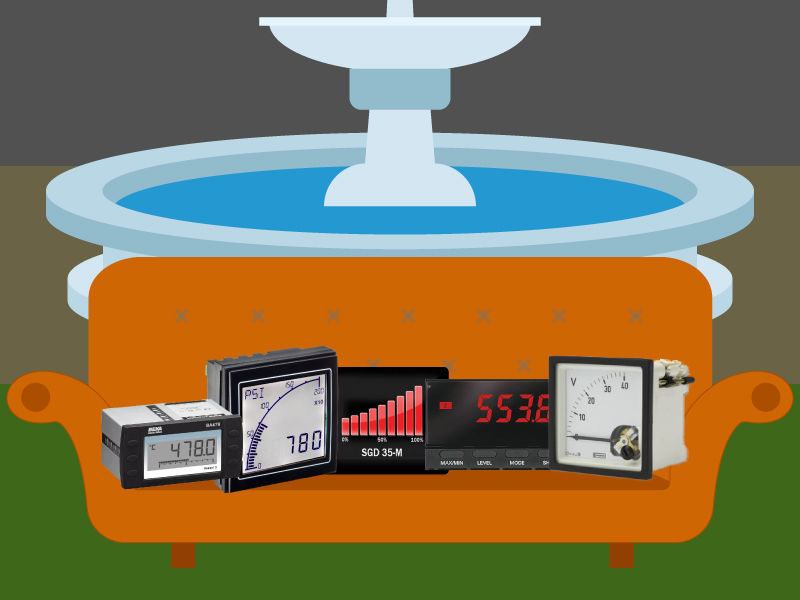

Panel meters come in all shapes and sizes for all manner of applications. Here, we take a peek at Kempston Controls Top 5 panel meters.