Kempston Controls and Lenze have formed a partnership to help bring you the best in intelligent automation product solutions.

A Pneumatic Connection – SMC Corporation (UK) Ltd. and Kempston Controls Team Up!

SMC Corporation (UK) Ltd. and Kempston Controls have combined to help bring you the best in pneumatic and automation and control products.

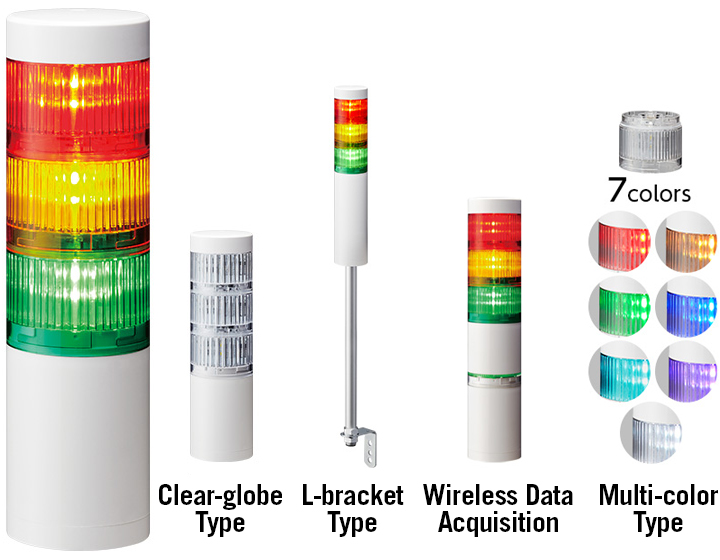

LR Series – LED Signal Towers – the Illuminating Choice, by PATLITE

The LR Series of Signal Towers are the perfect choice for harsh environment industrial signalling applications that you can depend on.

Lifting Africa with Dependable Crane Components from Kempston Controls Manufacturing

Cutler Hammer Compatible Crane Components from Kempston Controls Manufacturing. Reliability and durability, Made in Britain.

Kempston Controls LLC and Tele Haase Steuergerate – a new partnership is formed.

Tele Haase Steuergerate and Kempston Controls LLC have formed a partnership designed to bring you the best in monitoring, automation and control products.

Kempston Controls LLC joins forces with TEP Ex – an Explosion Protected Alliance

Kempston Controls LLC has joined forces with TEP Ex, a leading manufacturer of Ex-rated explosion protected electrical equipment.