Kempston Controls and Lenze have formed a partnership to help bring you the best in intelligent automation product solutions.

A Pneumatic Connection – SMC Corporation (UK) Ltd. and Kempston Controls Team Up!

SMC Corporation (UK) Ltd. and Kempston Controls have combined to help bring you the best in pneumatic and automation and control products.

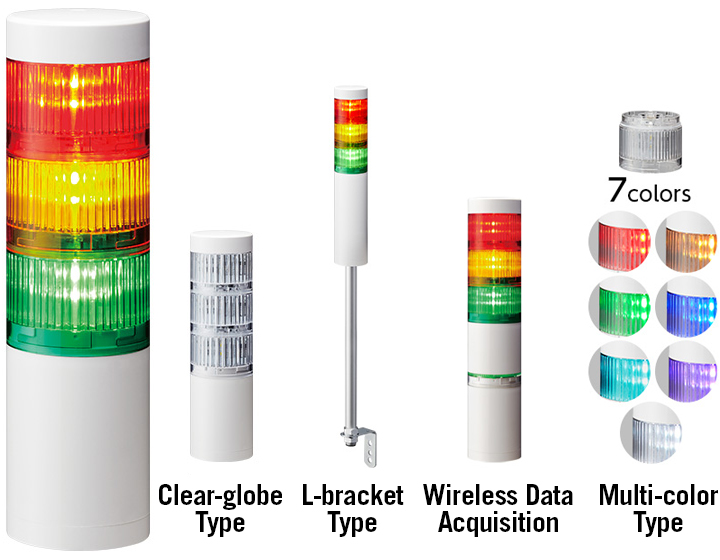

LR Series – LED Signal Towers – the Illuminating Choice, by PATLITE

The LR Series of Signal Towers are the perfect choice for harsh environment industrial signalling applications that you can depend on.

VISOR Object AI – Image Processing Made Better

The VISOR Object AI machine vision sensor from Sensopart, the intelligent way to vision monitor your manufacturing processes.

SLT Smart Light Tower from SICK – Industry 4.0 Signalling Made Easy

The SICK SLT Smart Light Tower brings ease of use and IO-Link Industry 4.0 technology to the demanding world of industrial signalling towers.

BN Series Control Devices from Pizzato, Capable, Versatile & Easy to Install

The BN series control devices, versatile modular products that are the perfect control solution for many industrial process control applications.