Soft Starters are designed to help reduce the inrush currents and limit the torque experienced by an electric motor by moderating a motors acceleration.

Food and Beverage Manufacturing? You can count on Kempstons for your MRO

MRO (Maintenance, Repair and Operation) products and equipment ensure your Food and Beverage production processes are kept functional at all times.

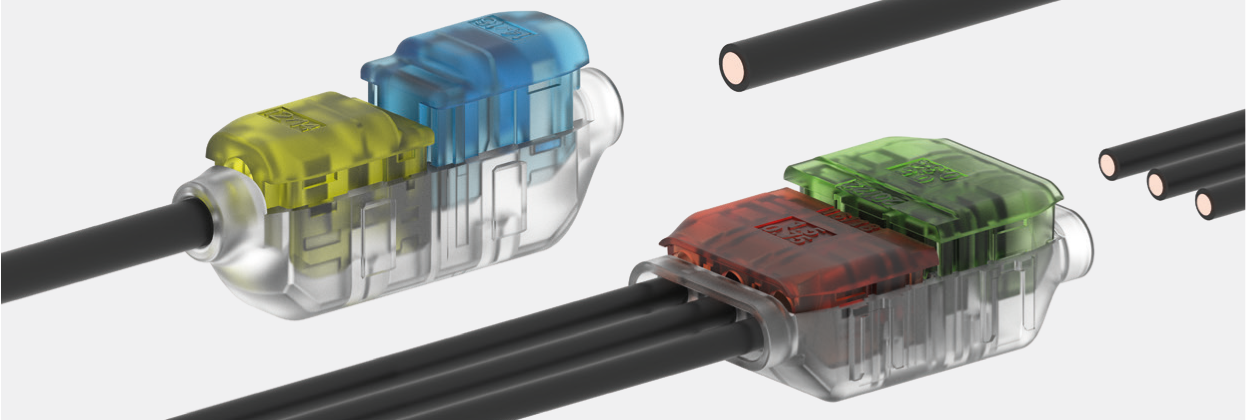

Coolsplice – IDC Connectors with the Edge

TE Connectivity’s CoolSplice connectors are a wire-to-wire insulation displacement connector (IDC) combining proven reliability with ease of termination.

Automation and Control Superiority from Schneider Electric Process Instrumentation

Schneider Electric Process Instrumentation is a global manufacturer of world-class quality instrumentation to the process industry, helping manufacturers achieve greater production throughput, improve quality, increase safety and reduce manufacturing costs.

Into the Blue with SensoParts’ BlueLight Photoelectric Sensors

Bluelight photoelectric sensors from SensoParts help alleviate many of the issue faced by regular photoelectric sensor technology, such as transparent, reflective and dark objects

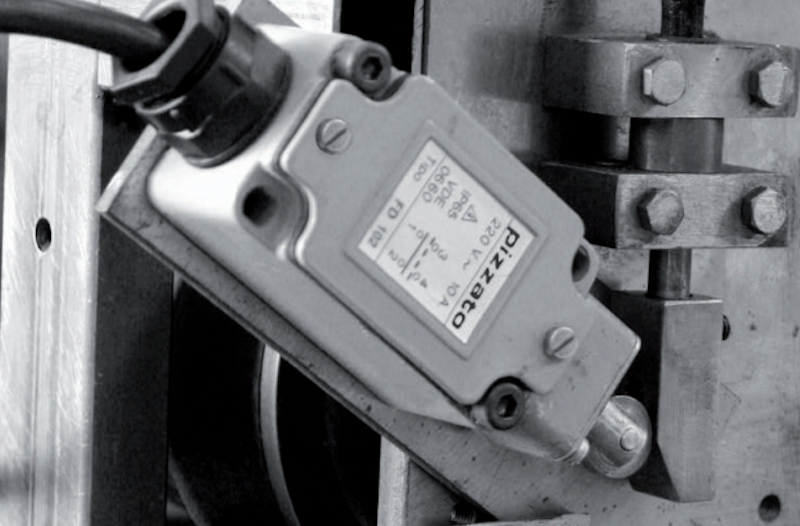

Limit Switches – Exceeding the Limits with the FD & FR Ranges from Pizzato

Pizzato has a comprehensive offering of limit switches and actuators covering all the applications that you are likely to encounter. We take a quick look at two of their limit switches options the FD and FR ranges.