When it comes to working environments were the danger of an explosive atmosphere exists, make sure you are ATEX safe.

What is a Safety Light Curtain – Why are they needed?

Safety light curtains have no doubt saved people from injury and death. But, users may not be making full use of their safety light curtains capabilities.

Kempston Controls LLC joins forces with TEP Ex – an Explosion Protected Alliance

Kempston Controls LLC has joined forces with TEP Ex, a leading manufacturer of Ex-rated explosion protected electrical equipment.

myPNOZ Creator – the Online Modular Safety Relay System Creation Tool

myPNOZ Creator is an online design tool for the simplified creation of Safety Relay Module assemblies. Built and Tested to your specifications and delivered to you.

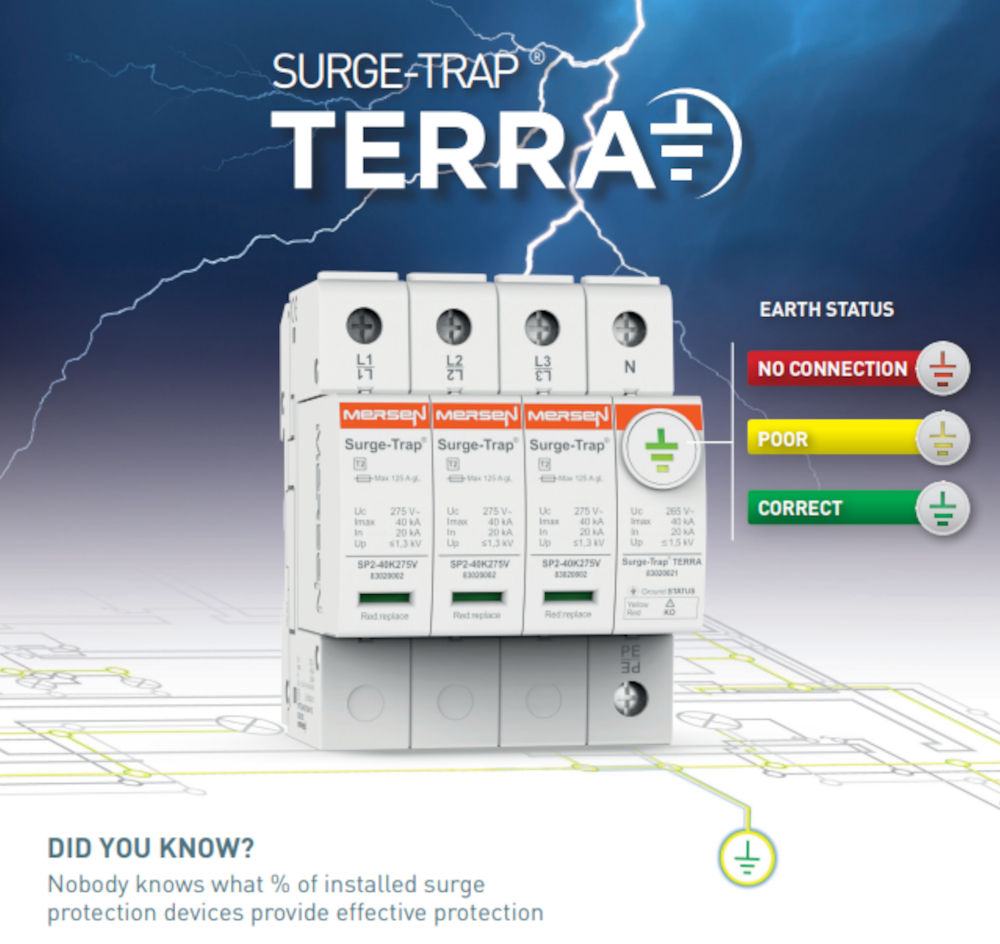

The Surge Trap TERRA – the Pinnacle in Surge Protection from Mersen

The TERRA Surge Protection devices from Mersen take the earth protection of your valuable installations to the next level.

Cable Management Solutions – Kempston Controls Partners with MENNEKES

Kempston Controls has Teamed up with MENNEKES to provide you with the best Power Cable Management products you can find.