Meet the Kempston Controls Thermal Solution Team! They are here to help provide you with advice on combustion plants, product selection, breakdowns, installation, and commissioning.

Working together – Kempston Controls and Sauter, a new HVAC and Combustion Supplier Partnership

Kempston Controls and Sauter have joined forces to bring you the best Building Management System products available.

VISOR Object AI – Image Processing Made Better

The VISOR Object AI machine vision sensor from Sensopart, the intelligent way to vision monitor your manufacturing processes.

A New HVAC and Combustion Supplier Partnership is Formed – Kempston Controls and Siemens

Kempston Controls are excited to announce a HVAC and combustion supplier partnership with one of the world’s leading manufacturers – Siemens!

myPNOZ Creator – the Online Modular Safety Relay System Creation Tool

myPNOZ Creator is an online design tool for the simplified creation of Safety Relay Module assemblies. Built and Tested to your specifications and delivered to you.

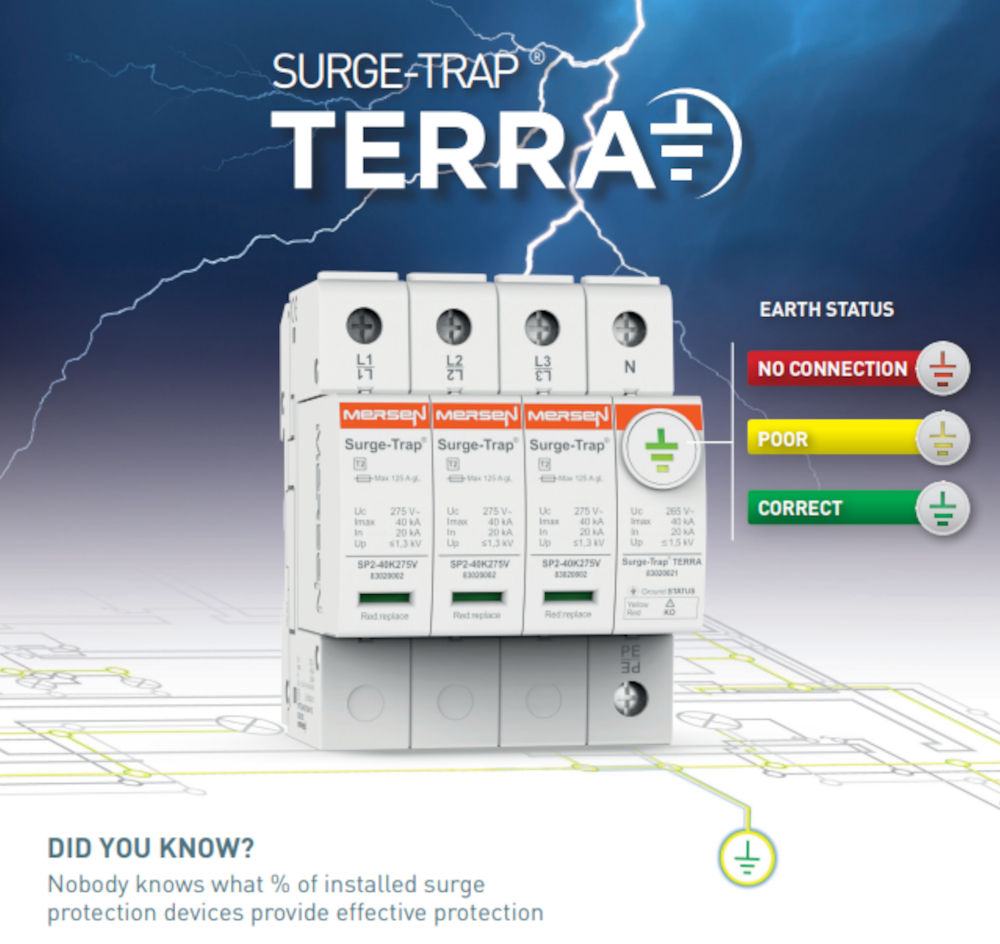

The Surge Trap TERRA – the Pinnacle in Surge Protection from Mersen

The TERRA Surge Protection devices from Mersen take the earth protection of your valuable installations to the next level.