It’s only January and Kempston Controls has signed up with the Building Controls and Industry Association (BCIA)! Read all about it!

A Pneumatic Connection – SMC Corporation (UK) Ltd. and Kempston Controls Team Up!

SMC Corporation (UK) Ltd. and Kempston Controls have combined to help bring you the best in pneumatic and automation and control products.

Camozzi Automation and Kempston Controls Team up!

Camozzi Automation and Kempston Controls have banded together to bring you the best in fluid management products.

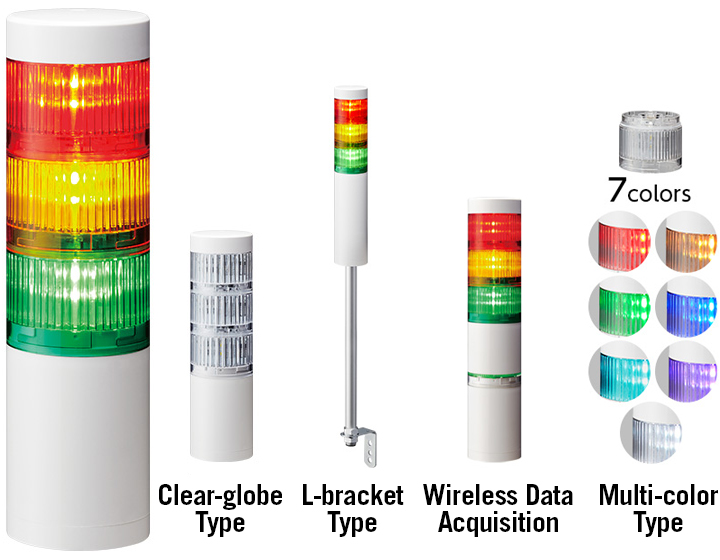

LR Series – LED Signal Towers – the Illuminating Choice, by PATLITE

The LR Series of Signal Towers are the perfect choice for harsh environment industrial signalling applications that you can depend on.

Kempston Controls LLC and Tele Haase Steuergerate – a new partnership is formed.

Tele Haase Steuergerate and Kempston Controls LLC have formed a partnership designed to bring you the best in monitoring, automation and control products.

Thermal Solutions – Meet the Team

Meet the Kempston Controls Thermal Solution Team! They are here to help provide you with advice on combustion plants, product selection, breakdowns, installation, and commissioning.