As you can imagine, an explosive atmosphere in the workplace can be very dangerous, leading to significant injuries and even death. Dangerous workplace atmospheres can be caused by flammable gases, mists, vapours, or combustible dusts. If these substances are present in a large enough volume and are combined with air and an ignition source, an explosion could occur.

It stands to reason that stopping the release of dangerous airborne substances, and preventing the sources of ignition are the most common ways of reducing the risk of explosion.

The Dangerous Substances and Explosive Atmospheres Regulations 2002 (DSEAR) places a duty on employers to eliminate or control the risks from explosive atmospheres in the workplace.

What is an explosive atmosphere?

According to DSEAR, an explosive atmosphere is defined as a mixture of dangerous substances with air under atmospheric conditions, in the form of gases, vapours, mist or dust in which, after ignition has occurred, combustion spreads to the entire unburned mixture.

Explosive atmospheres, where can they be found?

Countless working environments feature processes that could create explosive or potentially explosive atmospheres. Typical examples include those that create or release flammable gasses, mists and vapours, such as vehicle paint spraying, or places such as flour or sawmills where fine dust particles are present.

What is ATEX?

ATEX is the name commonly given to the two European Directives for controlling explosive atmospheres:

Directive 99/92/EC (also known as ATEX 137) on minimum requirements for improving the health and safety protection of workers potentially at risk from explosive atmospheres.

Directive 2014/34/EU (also known as ATEX 114) on the approximation of the laws of Members States concerning equipment and protective systems intended for use in potentially explosive atmospheres.

Explosive atmospheres in the workplace

In the UK, the requirements of Directive 99/92/EC were made effective through regulations 7 & 11 of DSEAR. These apply to workplaces where a potentially explosive atmosphere may occur. Certain sectors and work activities are exempt due to other legislation that is listed in regulation 3 of DSEAR.

DSEAR – What does it require?

DSEAR insists employers eliminate or control the risks from dangerous substances – more information can be found in DSEAR. Additional to the general requirements, the regulations place the following duties on employers with workplaces where explosive atmospheres may occur.

Classification of explosive atmosphere areas

Areas where hazardous explosive atmospheres may occur must be classified into zones. The classification of a zone, its size and location, depends on the likelihood of an explosive atmosphere occurring and its persistence if it does. Schedule 2 of DSEAR contains descriptions of the classifications of these zones.

Protective systems and equipment

Classified zones must be protected from sources of ignition. Equipment and protective systems in these areas should meet the requirements of the Equipment and Protective Systems Intended for Use in Potentially Explosive Atmospheres Regulations 1996. Equipment in use before July 2003 can continue to be used providing a risk assessment has been undertaken.

Identifying the ATEX Zones

Where required, entry points to classified zones need to be marked with a specified ‘EX’ sign.

Antistatic clothing

Employers must provide employees in zoned locations with clothing that cannot create electrostatic discharges which could cause ignition, for example – antistatic boots. The clothing required depends on the risks identified during the risk assessment.

Verification of explosion safety

Prior to a zoned areas start-up, the employer must ensure that explosion safety measures are safe. A person or organisation trusted to evaluate the risks has to perform this task, along with the adequacy of the explosion control equipment and any further measures.

Equipment and protective systems used in explosive atmospheres

Directive 2014/34/EU was created is to allow the free trade of ATEX equipment and protective systems within the EU by removing the need for separate testing and documentation for each Member State.

The requirements of the Directive in the UK were put into effect through BIS Equipment and Protective Systems Intended for Use in Potentially Explosive Atmospheres Regulations 1996 (SI 1996/192). This applies to equipment intended for use in explosive atmospheres and associated protective systems.

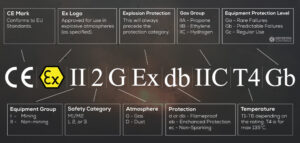

Manufacturers/suppliers (or importers, if manufactured outside the EU) must ensure their products meet H&S requirements and undergo conformity procedures. This can involve testing and certification by a ‘third-party’ certification body (Notified Body). Manufacturers/suppliers can ‘self-certify’ equipment intended for use in less hazardous zones. Once certified, the equipment is marked by the ‘EX’ symbol.

The certifications ensures that the equipment is fit for purpose and that information is supplied with it to ensure it is used safely. BIS has policy responsibility for the Regulations, although HSE enforces them.

Regulations and directives are regularly updated and modified – so please make sure that you are up to date with the latest directives and regulations outlined above.

Find our ATEX related products

Have you seen these?

Kempston Controls is committed to finding you the ideal solution for your application. Call us today on +44 (0) 1933 411 411, email us at sales@kempstoncontrols.co.uk, or alternatively contact us here, we will be happy to help.