Many industrial manufacturing applications such as processing conveyors, pick and place machinery and robotic systems depend upon speed and position feedback and monitoring to ensure that they are operating effectively and efficiently. Incremental encoders help provide position and motion information by converting movement and the relative position of a shaft into an analogue or digital signal that is then interpreted by the installations control system.

Intelligent Sensor Solutions

SICK is one of the world’s leading manufacturers of intelligent sensors for industrial applications, with decades of experience across a wide range of industries giving them the extra insight needed to push the design envelope.

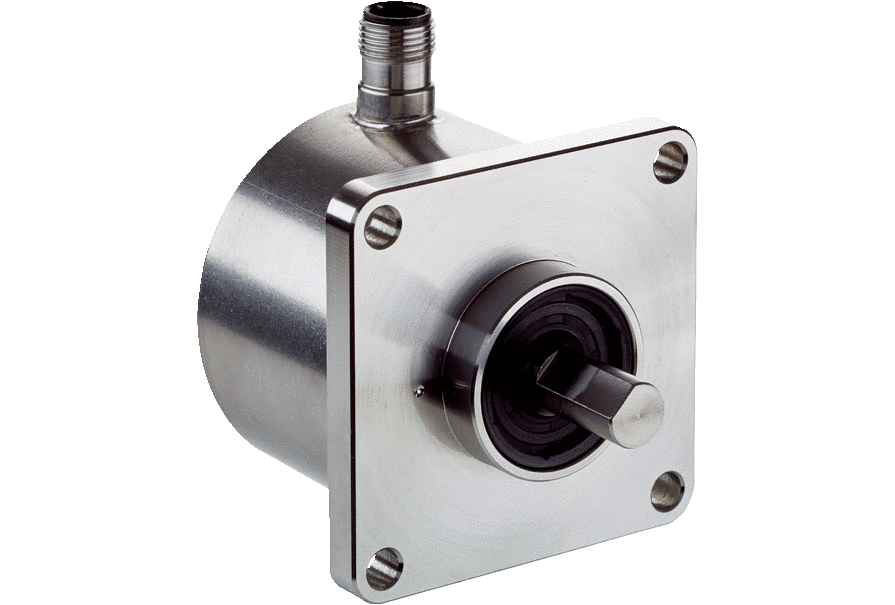

The DBS60 Inox range of Incremental Encoders, with their rugged stainless-steel construction and excellent environmental protection are the perfect position and speed monitoring encoders for challenging working environments.

The combination of a complete stainless-steel design and the durable shaft seal make the DBS60 Inox incremental encoders resistant to countless demanding working environments such as those found in the food and beverage industry. The Inox’s 58mm diameter stainless steel housing comes with IP67 or an IP69K (model dependent) enclosure rating, meaning it is ideal for challenging applications which also have limited installation space. The IP69K DBS60I-W* version with its built-in deflector shield, which protects the encoders shaft seal, is the ideal product solution for applications where high-pressure warm-water washdowns are the norm.

Demanding Environments

With a resolution of up to 5000 pulses per revolution and a wide variety of mechanical and communication interfaces the DBS60 Inox Incremental Encoder Range is ideal for many different fields of industry, including food and beverage, medical & chemical, robotic systems, packaging machines and offshore installations.

DBS60 Inox Incremental Encoder Features

- Stainless steel construction- high level of resistance to environmental conditions

- Pulses per revolution – 0 to 5000

- Blind hollow shaft or solid shaft with face mount flange or square flange

- Shaft diameters 6, 8, 10, 12, 14, 15 mm and 3/8”

- Male connector M12 – 8 pin, 5 metre cable

- Communication Interfaces: TTL/HTL, TTL/RS-422, HTL/push-pull

- Protected against aggressive media and cleaning agents

- Bacterial growth prevention through clean design (IP69K variant)

Have you seen these blogs?

Speed Monitoring without Contact

Kempston Controls is committed to finding you the ideal solution for your application. Call us today on +44 (0) 1933 411 411, email us at sales@kempstoncontrols.co.uk, or alternatively contact us here, we will be happy to help.