The SICK RFU61x RFID Sensor packs big features into a small package, ideal for production control monitoring in demanding conditions.

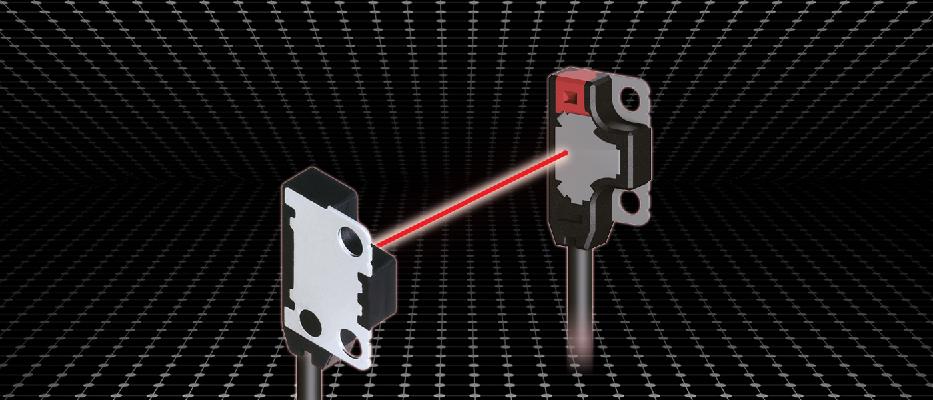

EX-Z Series Photoelectric Sensors – Small is Beautiful

EX-Z Series of Miniature Thru-beam Photoelectric Sensors is one of the smallest in the world with an internal amp. Ideal for mounting in tight spaces!

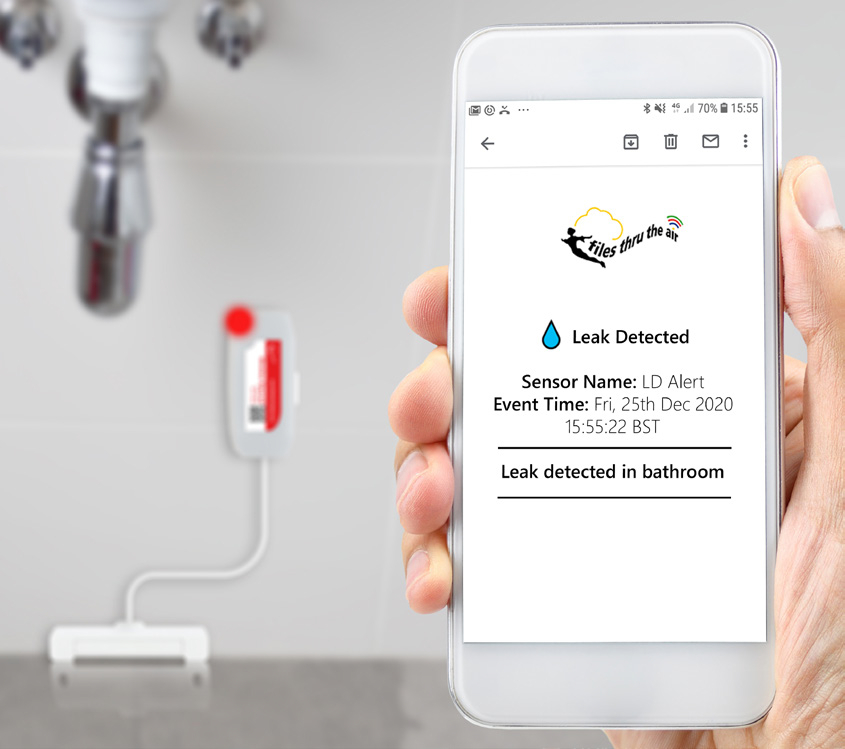

The Wireless Alert Sensor Range from Lascar Expands!

Lascar have expanded their Wireless Alert Range with the addition of three exciting Wi-Fi enable sensor products.

SicWave – 80 GHz Free-space Radar Level Detection for all Liquids and Solids

SICK’s LBR and LFR 80 GHz narrow beam radar level detection sensors for liquids and solids are the ultimate in level sensing technology.

Safety Light Curtains with Advanced Bluetooth Interface

Schmersal Safety Light Curtains with advanced BLE Bluetooth communication are adding the next level of safety & control to your process.

Baumer’s POG 83 Series Rotary Encoders, Built for a life at Sea

POG 83 Incremental Rotary Encoders have been designed to survive the rigours and perils of a life at sea.