On the 1st of July we attended a careers fair at The Ferrers School in Higham. It was a fantastic opportunity to converse with their year 12 students, we spoke about their career aspirations and informed the students about our apprenticeship schemes and the many job opportunities we have to offer. We later returned to […]

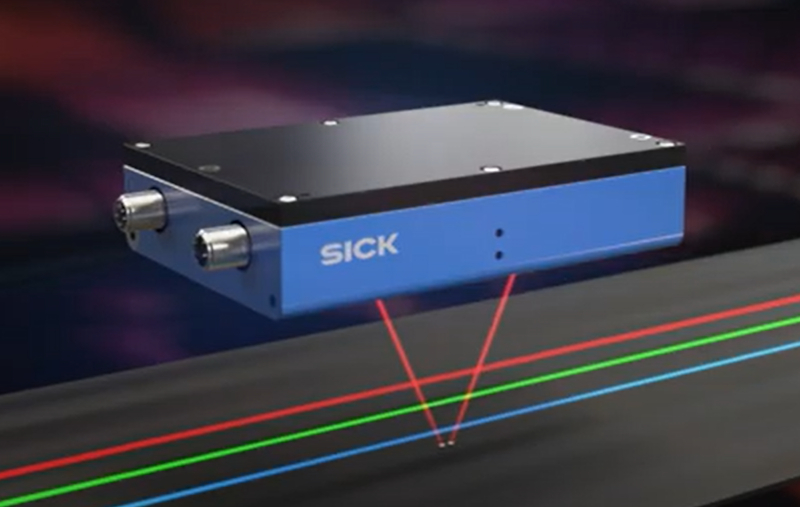

Kempston Controls and the SICK SPEETEC Sensor Help Solve a Real Steel Processing Problem

The SPEETEC Sensor from SICK and Kempston Controls helped solve a tricky issue TATA Steel faced with steel tube production.

SICK PBS plus Pressure Sensor – Added Versatility for Pressure Monitoring Installations

The PBS plus Pressure Sensor Range is the perfect sensor for demanding industrial applications, providing a robust electronic pressure switch, transmitter and display all in one.

SicWave – 80 GHz Free-space Radar Level Detection for all Liquids and Solids

SICK’s LBR and LFR 80 GHz narrow beam radar level detection sensors for liquids and solids are the ultimate in level sensing technology.

SPEETEC Sensors -Motion Capture without Contact

SICK SPEETEC contact free motion detectors are the perfect solution for measuring delicate and soft materials that could be damaged or deformed by mechanical measuring wheels.

PowerProx Sensors – Powerful Photoelectric Sensing in Miniature

SICK has taken its ultra-reliable, high-performance, PowerProx sensor and shrank all that technology into a space-saving miniature housing.