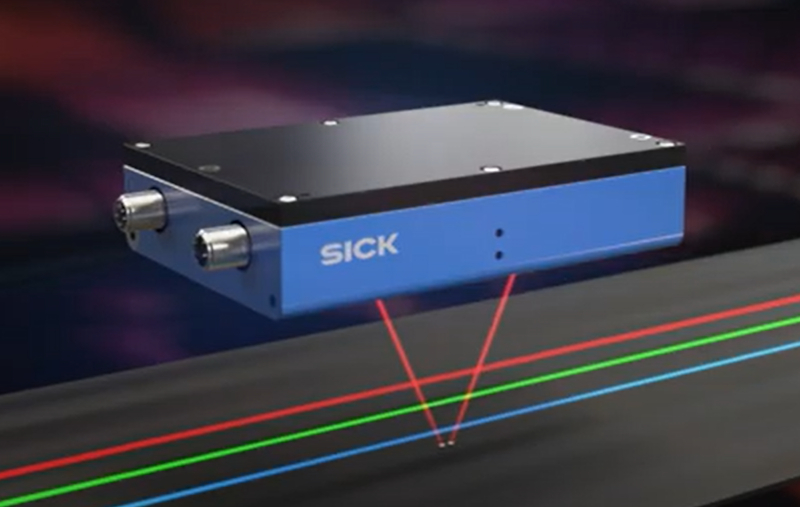

The SPEETEC Sensor from SICK and Kempston Controls helped solve a tricky issue TATA Steel faced with steel tube production.

Ultrasonic Sensor Technology for Safety in All Areas with the Pepperl + Fuchs USi- safety

The USi-safety ultrasonic sensors from Pepperl + Fuchs. Advanced safety sensors, ideal for protecting machines, vehicles and people in demanding conditions with elliptical sound field technology.

SICK PBS plus Pressure Sensor – Added Versatility for Pressure Monitoring Installations

The PBS plus Pressure Sensor Range is the perfect sensor for demanding industrial applications, providing a robust electronic pressure switch, transmitter and display all in one.

ST-G RFID Sensors with Multi-tag Ability for Industrial Process Control and Safety Applications

The Pizzato ST-G RFID Sensors are ideal for Process Control and Safety Gate Applications, with sensors capable of recognising up to 16 actuators per installation.

Indoor Air Quality monitoring with the Lascar EL-WEM

The quality of the air we breathe indoors is becoming more and more important. Monitoring the air you breath is easy with the Lascar EL-WEM.

O200 Miniature Photoelectric Sensors- Shiny, Transparent, Deep-Black Object Detection Made Easy

The Baumer 0200 Photoelectric Sensors have been designed for the most demanding object detection tasks, from transparent to deep-black products, this range has you covered.