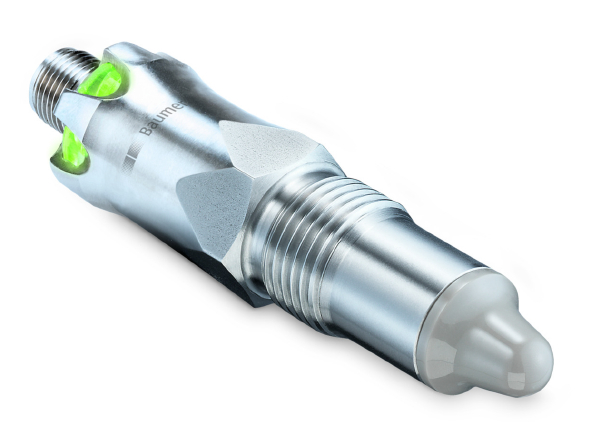

Down with Vibrating Fork Sensors, long live the King! The KingCrown CleverLevel PL20 Series Level Sensors are setting the stage as the most dependable and versatile level detection solution for a wide variety of troublesome media and processes.

With an adaptive-trigger function, these capable level sensors are a step ahead of vibrating fork sensors, automatically adjusting to all media without parameterisation. Applications vary from dry running protection for pumps through reliable overfill protection or leak detection to the selective detection and masking of foam or separating layers.

360 Degree Process Visualisation, Even in Daylight!

Robust process visualisation is built-in using 360° LEDs which provide real-time information on the process status, with 5 defined colours which can indicate whether the process is working as intended, the sensor is switching, or if there is an issue. Additionally, the colours can be used to indicate which medium is being measured and analogue values ranging from 4…20mA can be read out.

It doesn’t matter whether it’s bulk goods, powders, liquids or foam, or if the medium is sticky or has high or low viscosity, the KingCrown Level Sensor is the new King in town!

During industrial cleaning processes, such as CIP cleaning, sensors can switch incorrectly as they cannot differentiate between the process and cleaning media. The PL20 Level Sensors master this challenge by ignoring cleaning media. Also, media adherence, which can be caused by pasty materials, doesn’t affect these sensors, which adjust their switching level without the need for parameterisation.

Hot, Humid, No Problem!

In very humid areas, or those with temperature changes or water spray, a rugged impermeable design is needed to prevent sensor malfunctions. With exceptional resistance to impacts and fracturing during installation and production the KingCrown PL20 Series is perfect for demanding working conditions. Designed according to Baumers proTect+ Impermeability Concept, the PL20 Level Sensors are ideal for these challenging conditions. (Learn more about the Baumer proTect+ here).

Beverage and Rugged Industrial Application Versions

A built-in IO-Link interface provides easy access to valuable data, additionally it allows easy, location-independent parameterisation of the level sensor.

Available in two versions, with multiple mounting options, the PL20H for Food and Beverage process use and the PL20S variants for demanding high-pressure industrial applications.

PL20 Series Level Sensor Features and Benefits

- 5 Multicolour LEDS, 360° real time status display even in daylight

- Versions for Hygienic and Industrial applications, can be used in open tanks

- Long term impermeability over entire service life according to Baumer proTect+

- Measuring principle – Frequency sweep

- IO Link interface

- IP68 and IP69K protection rating

- Impact and fracture resistant

- PNP, NPN Output types, NO, NC, short circuit protected

- Unaffected by temperature changes

- Electrical connection made of stainless steel

- Suitable for use in outdoor, hygiene and washdown applications

- Point level sensor with automatic parameterisation with changing media and adherence

- Universal for liquids and bulk materials (DK >1.5)

- Separately adjustable switching outputs with IO-Link, optional 4 – 20 mA analogue output

With a reduction in the wide variety of components needed by using the same sensor type has many advantages including procurement, spares and maintenance costs. The development of new plant and machinery is also more efficient and the large number of available process connections and adapters available for the PL20S and the PL20H Level Sensors simplifies integration into existing systems.

Get in Touch

Have you read these?

Kempston Controls is committed to finding you the ideal solution for your application. Call us today on +44 (0) 1933 411 411, email us at sales@kempstoncontrols.co.uk, or alternatively contact us here, we will be happy to help.