Pepperl + Fuchs Ethernet IO modules with integrated IO-Link master provide first rate communication between PLCs and process sensors and actuators.

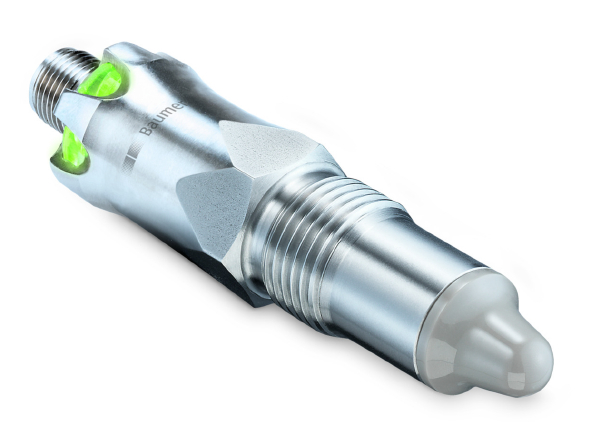

The King of Level Sensors – The KingCrown CleverLevel PL20 Series from Baumer

The Baumer KingCrown CleverLevel Level Sensors are a step above the competition. Ideal for Harsh Hygenic and Industrial Applications that utilise difficult media.

SICK PBS plus Pressure Sensor – Added Versatility for Pressure Monitoring Installations

The PBS plus Pressure Sensor Range is the perfect sensor for demanding industrial applications, providing a robust electronic pressure switch, transmitter and display all in one.

O200 Miniature Photoelectric Sensors- Shiny, Transparent, Deep-Black Object Detection Made Easy

The Baumer 0200 Photoelectric Sensors have been designed for the most demanding object detection tasks, from transparent to deep-black products, this range has you covered.

Distance Sensors when Precision Matters – the Panasonic HG-C

The Panasonic HG-C distance sensors are ideal for numerous measuring task, such as the height of a robotic arm, hoop slack or checking for the presence of O-rings.

R2000 2-D Lidar Sensors – Sensors with Depth Perception

The R2000 Series of LiDAR Sensors from Pepperl + Fuchs, an exceptional sensing solution for Position and Navigational systems.