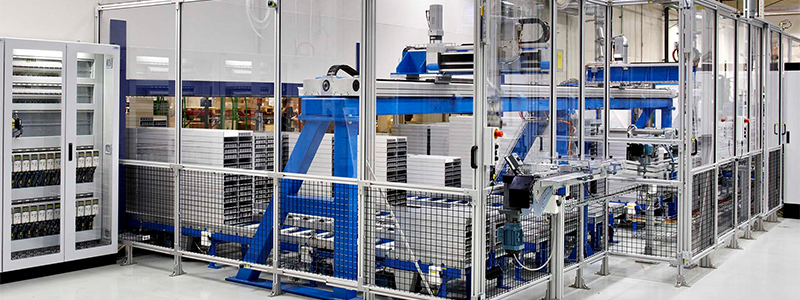

Designed to be flexible, the Quick-Guard fencing system is ideal for a variety of applications from machine enclosures to preventing access to hazardous areas.

Consisting of different components, such as aluminium profiles, patented assembly parts, netlocks, mesh, solid or noise reduction panels the Quick-Guard system can be tailored to meet any requirement.

Thanks to ABB’s patented screw-lock system, all the brackets are supplied premounted with fixing screws and nuts. Due to the profile’s T‑slot, assembly and any further modifications can be easily made.

Quick-Guard at a glance

Easy to install

- Lightweight aluminium profiles allowing for ergonomic assembly.

- Premounted brackets with a patented screw-lock system to simplify assembly.

- Easy to modify an existing fence design since the aluminium profiles are easy to saw into different lengths.

Speed up your projects

- Endless possibilities with numerous materials and components

- Quick-Guard fencing has fittings and mounting brackets for sensors, locks and switches from the ABB Jokab Safety range.

Applications

ABB’s Quick-Guard fencing system has been designed to be used in a multitude of applications and can easily be customised to suit any requirement. Quick-Guard can be supplied in two formats: Quick-Guard Express and Quick-Guard Standard.

Quick-Guard Express can be installed quickly and is ideal as a cost-effective fencing solution. The customer orders ready-made sections consisting of a few components which makes it easy to install on-site.

Quick-Guard Standard is more advanced than the Express version and uses a sketch or an AutoCAD file of how the user wants the fencing system to look. The information is then transferred to SafeCAD (ABB’s free AutoCAD plugin) and a 3D model of the user’s requirements is rendered with cutting, component lists and quotations automatically generated.

What’s more, these two fencing systems can be combined to achieve a complete system.

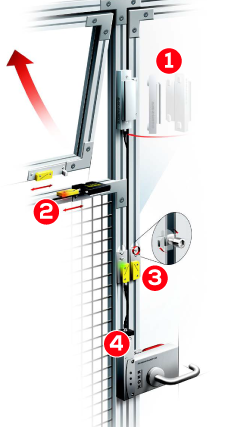

Patented assembly function

ABB’s patented guide and locking method allows for simple assembly while keeping expansion easy. The integrated fixing nut can be easily be located within the profile and automatically positions itself when the screw is turned 90 degrees clockwise to allow adjustments. While the fixing nut is in this position, the bracket being fitted can be adjusted and then locked by turning the screw clockwise. To remove the bracket the fixing screw is turned counterclockwise.

Customisable and integrated components

ABB offers a wide range of sensors and control devices specifically designed for the Quick-Guard fencing system. Devices such as Sensors, light grids and emergency stops are easy to mount, adjust and dismount thanks to the profile’s T‑slot and special nuts. The patented assembly means no holes have been drilled so there’s no holes or damage when adjustments are made – keeping the system professional, safe and secure.

Integrated components available:

- Eden – Non-contact sensor – (3)

- Orion – Optical safety device

- Smile/Inca – Emergency Stop

- ASK – Pressure-sensitive safety mats

- Contactors & electronic starters

- Magne – Magnetic process lock – (1)

- MKey – Mechanical key switch

- EStrong – Emergency stop

- GKey – Safety lock

- Dalton – Process lock – (2)

- Knox – Safety lock – (4)

The Quick-Guard fencing system from ABB is the ideal solution for protecting machine enclosures and more. To find out how the solution could work for your application, contact Kempston Controls today on +44 (0) 1933 411411 or email us at sales@kempstoncontrols.co.uk.

Have you seen these articles?

Making your life easier… Kempston Controls industry-leading Request a Quote feature!

“Say ATEX RATED!” – The Cube 800: Intrinsically safe camera and thermal imager

Kempston Controls is committed to finding you the ideal solution for your application. Call us today on +44 (0) 1933 411 411, email us at sales@kempstoncontrols.co.uk, or alternatively contact us here, we will be happy to help.