What is Mechanical Strain?

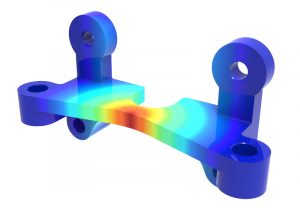

Mechanical strain is the relative change in the length of a component or a structure when a stress is applied. Strain can be from the results of external forces, mechanical strain and from the effects of thermal expansion or contraction experienced during temperature changes. The indirect force measurement taken by strain sensors determines the mechanical strain experienced by the component or structure being monitored.

Strain sensors come in a wide variety of variants including wire strain gauges, bolt strain gauges, shear strain gauges, columnar strain gauges and many more besides. Where the application has a restriction of available real estate, but the potential strain could be large you will need a dependable, miniature strain gauge with the capacity to do the job well, enter the Baumer DST20 Miniature Strain Sensors.

Strain Sensing

The DST20 Miniature Strain Sensors are a compact and cost-efficient solution for measuring large forces above 10,000 N, even in areas with restricted space. A diminutive 28 x 12 x 10 mm in size, these capable miniature strain sensors provide space saving and reliability that is unmatched by any other screw-on strain sensor on the market.

With stainless-steel housings and an IP65 protection rating these strain sensors are ideally suited for use in a wide range of demanding production environments and applications, including static and dynamic applications, process automation and mechanical engineering sensing tasks.

Static and Dynamic Loads

Easy to install, the DST20 strain sensors can be integrated into an application with the minimum of engineering effort and provide a lasting solution that can replace cold bonded strain gauges in space restricted installations. The compact DST20 miniature strain sensors are suitable for static as well as dynamic applications with strain gauge technology that features a strain gauge and a strain body. The soft geometry on the inside of the sensor minimises hardening of the structure being measured and even thin structures can be monitored because of the limited reaction forces on the mounting screws.

The strain of these sensors is typically measured with an output signal of around 1.0 mV/V when they leave the factory, this eliminates the need for calibration with a separate force sensor. This allows Installation Engineers to benefit from a quick and easy commissioning coupled with a high measurement accuracy in the micrometre range.

Versatile Sensing

These versatile sensors are available in two measurement ranges – 500 and 1,000 µm/m, for different customer requirements in terms of the expected strains and permitted mechanical tension depending on the steel quality. A single sensor can be used to cover a wide range of applications, allowing customers to reduce costs and reduce the need for additional storage space.

With the DST20 strain sensor range Baumer has rounded off its strong portfolio of force and strain sensors so customers can optimise their process safety and quality where the smallest dimensions matter.

Get all your Baumer Strain Sensors from Kempston Controls today! Our friendly sales team are on hand to take your call, you can get through to them on +44 (0) 1933 411 411 or email sales@kempstoncontrols.co.uk, or use the ‘contact us’ link above.

Have you read these articles?

Kempston Controls is committed to finding you the ideal solution for your application. Call us today on +44 (0) 1933 411 411, email us at sales@kempstoncontrols.co.uk, or alternatively contact us here, we will be happy to help.