The Conventional infrared though beam sensors found in many manufacturing installations can generate unexpected malfunctions that could lead to many hours of investigation and maintenance to resolve. Panasonic design engineers embraced this situation as a challenge, find a way to simplify this investigative process and make life easier for the operators and engineers involved in the tasks at hand, ultimately saving companies time, money and a lot of hassle!

Designed for use on manufacturing and processing lines, the HG-T Series Laser Through-beam Sensors feature a built-in self-monitoring function that diagnoses the current operational state and notifies the user when readjustment of established settings have drifted and when maintenance is required. The sensor determines its status and indicates Normal, Notification, Caution or Fault via its controller. When not in its normal status, the sensor identifies the cause of the problem and the corrective measures required, reducing equipment downtime and maintenance workload.

Finding the Edge

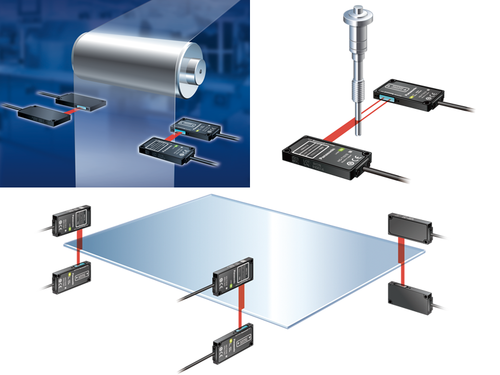

A HG-T Laser Through-beam Sensor installation, which consist of an emitter, receiver unit and a controller, produces a flat, belt-shaped laser beam with a height of 10 mm which is ideal for tasks such as checking the contours of an edge, shaft diameters or the inside diameter of a product. The sensors have a sensing range of 500 mm, achieving a repeatability of < 1µm and have a linearity of less than ± 12µm over their measurement range, meaning that they are suitable for a wider range of applications than those infrared sensors with a shorter sensing distance.

Quick to install, the sensor heads are equipped with a beam alignment function to help speed up commissioning. Easy to set up by simply plugging the sensors into the controller unit which then automatically detects whether the emitter and receiver are connected correctly.

Available in two different sensor head versions, both with the same capabilities and only differing in their physical dimensions. The receiver of the slim version is 10 mm narrower than the standard model making it suitable for installations with very limited space where the standard version would perhaps be too large.

HG-T Sensors Model Numbers – HG-T1010, HG-T1110 Features

- Compatible controllers – HG-TC101, HG-TC111, HG-TC113

- CMOS based position detection

- Measurement range – 10 mm

- Sensing range – 0 to 500 mm

- Supply voltage 24 Vdc, voltage output range 0 to 5 V

- NPN, PNP output types

- Poly carbonate casing, 2 metre cable, IP67 rated

- Red semiconductor laser, class 1 (IEC/JIS/GB/FDA) Max. power of the emitting element 0.3 mW, laser wavelength 655 nm

- Repeatability 1μm (installation distance: 20 mm) 2.5 μm (installation distance: 100mm) 5μm (installation distance: 500 mm)

- Linearity ±0.12% F.S. (installation distance: 20 mm) ±0.28% F.S. (installation distance: 100 mm)

- Object to be sensed Min. ø 0.5 mm (installation distance: 500 mm)

- Standards – EMC Directive, RoHS directive, FDA regulations

The HG-T Laser Through-beam Sensor Controller

The HG-T Through-beam sensor controller unit (purchased separately or as part of a kit) is equipped with a current voltage output that can be selected according to the application requirements. A 2 line digital display simultaneously shows the sensor head measured value the calculated value with an intuitive circle meter helping to display the values in a simple way. Six types of detection mode to select from make commissioning with this controller easy. External inputs allow the user to control laser emission, reset the device or save data during the process, supports high-speed sampling with a frequency of up to 2kHz.

- Six types of detection mode

- Auto edge detection mode

- Edge detection mode

- Inside diameter / gap detection mode

- User assigned edge detection mode

- External form / width detection mode

- Central position detection mode

Outstanding sensor performance

Thanks to functions like filters, edge detection, light intensity checks and averaging of measurement values (up to 1024), means that the measured parameters can be relied upon. These functions help you to detect, at an early stage, when the measuring process isn’t running correctly and attention is needed.

Multiple sensors

The master-slave system allows you to connect up to 15 laser through beam sensors in series. Another handy and time saving feature, increasing ease-of-use, is the ability to copy settings from the master to the slave units, with an LED indicating when copying is in progress.

HG-T Laser Through-beam Sensor Applications

- Guiding the sheet edge of battery electrodes

- Checking diameter and position of threads or wires

- Detection of individually stacked wafers

- Guiding of translucent films

- Measuring of drill holes in motor components

- Measuring the material thickness of films or textile webs

- Highly precise measuring and checking of web edges

- Glass substrate positioning

- Diameter measuring

Note: The optional side view mirror makes it possible to deflect the beam by 90°.

Kempston Controls has a long-established relationship with Panasonic which gives us access to their entire product portfolio. Speak to us today either by phone on +44 (0) 1933 411 411, email via sales@kempstoncontrols.co.uk or using the contact form below. We will be happy to discuss your requirements and help you ensure that your new installation or retrofitting project goes exactly as planned.

Enquire Now

Have you read these?

Kempston Controls is committed to finding you the ideal solution for your application. Call us today on +44 (0) 1933 411 411, email us at sales@kempstoncontrols.co.uk, or alternatively contact us here, we will be happy to help.