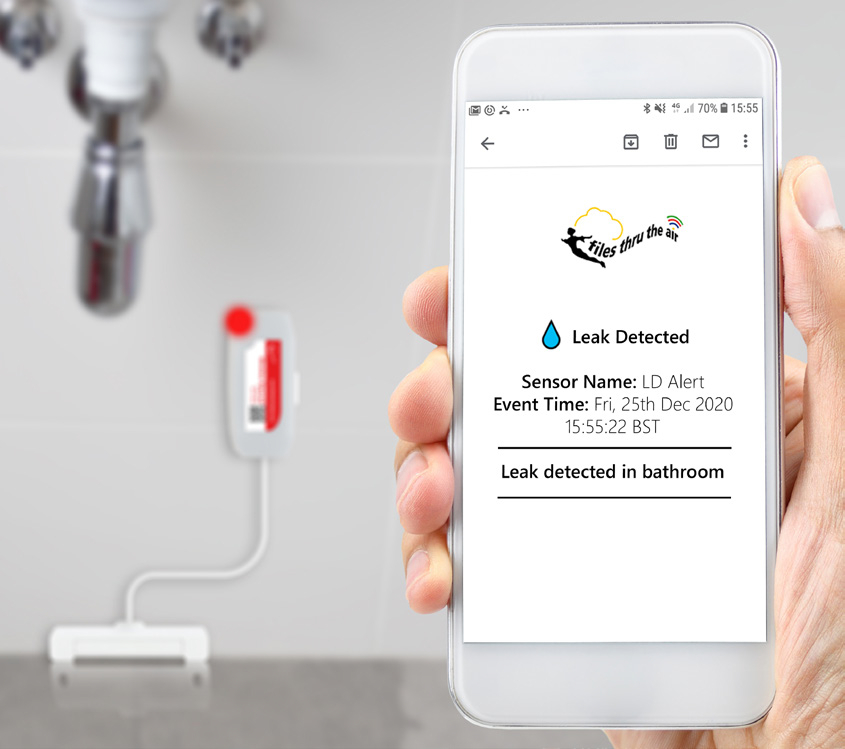

Lascar have expanded their Wireless Alert Range with the addition of three exciting Wi-Fi enable sensor products.

SicWave – 80 GHz Free-space Radar Level Detection for all Liquids and Solids

SICK’s LBR and LFR 80 GHz narrow beam radar level detection sensors for liquids and solids are the ultimate in level sensing technology.

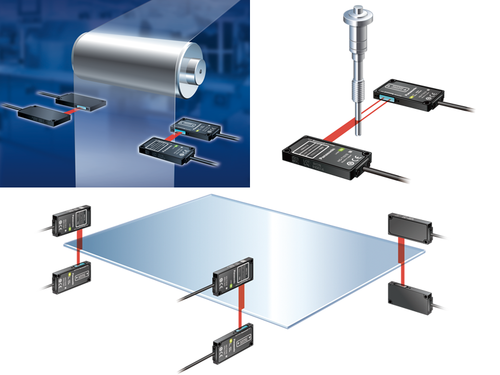

A Laser Through Beam Sensor with the Edge

The HG-T Laser through beam sensor range from Panasonic. When it comes to dependable edge, contour & gap detection and guiding translucent film you can’t go wrong.

APM-MAX 21 and 23 Panel Meters, Process Signal & Power Monitoring in Full Colour!

The APM-MAX 21 and MAX 23 panel meters for engineers who need an effective way to monitor and display a range of process signal & power monitoring data.

Sirius Act ID Key-Operated Switch Starter Kits!

Siemens SIRIUS ACT ID Key-Operated switches are the perfect solution when it comes to safety door and access monitoring.