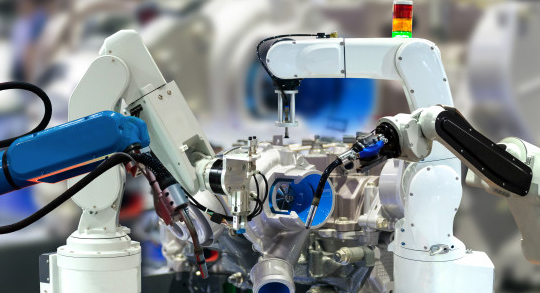

Industry 4.0 is known as the fourth industrial revolution, changing the way we manufacture a vast spectrum of products, thanks to the digitisation of the mechanisms involved in their creation

IO-Link for safety light curtains

With the development of the SF4D safety light curtain series, Panasonic has once again proven the quality of their automation products: The SF4D has been adopted very fast and successfully in various industries.

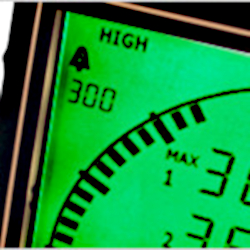

trumeter Advanced Panel Meters – Helped BEST get Better

Do you need a panel mount display solution that features the visible advantages of an analogue display but with the added advantages of digital accuracy? Look no further…

Ultra-Low Emissions. Will you be Leading the Charge When it Comes to Electric Vehicle Supply Networks?

In 2018 the UK Government launched its Road to Zero strategy, with ambitious targets of at least 50% and as many as 70% of new cars constructed to be ultra-low emissions by 2030 and by 2050 they want almost every car and van to be zero emission.

Full-Scale Monitoring, Measuring and Protection with Crompton Instruments from TE Connectivity

The extensive range of Crompton Instruments products available from Kempston Controls includes a wealth of measurement technology products that today’s applications require for efficient and effective energy management.